Performance

Durable Collaborative

robots for your automation

Flexible deployment with

safe feature

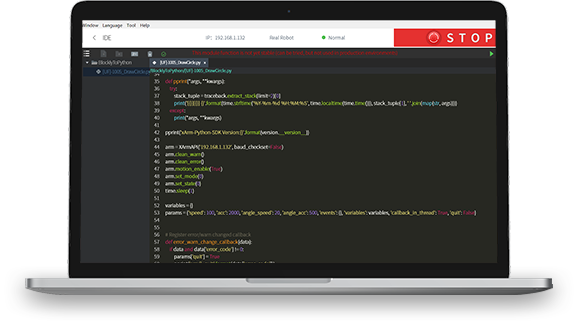

Graphical interface for

beginner-friendly programming

Powerful and open source

SDK at your fingertips

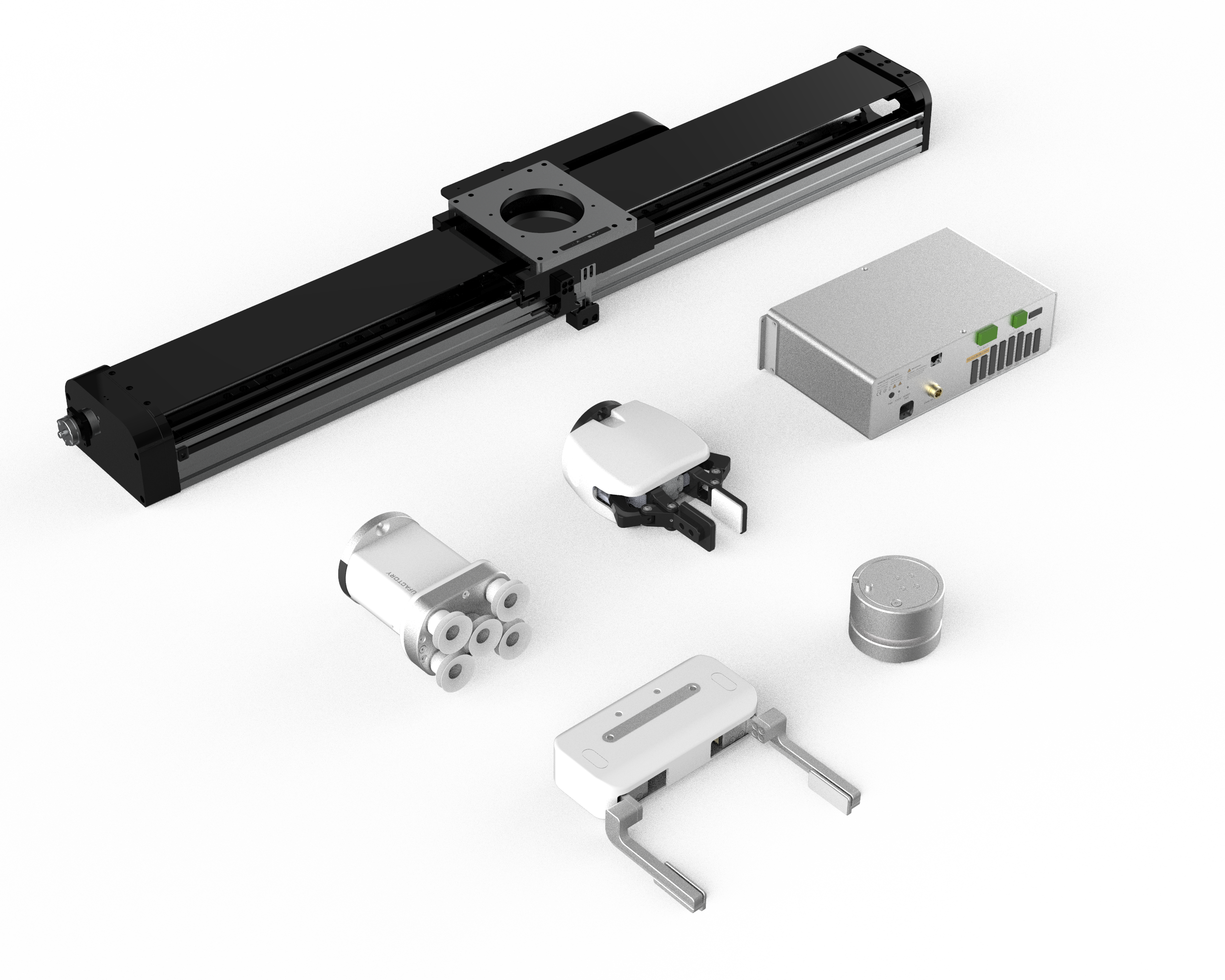

Seamless integration with

official accessories

Our robot arm can equip with a range of accessories to easily achieve the application you need.

Beginner-friendly

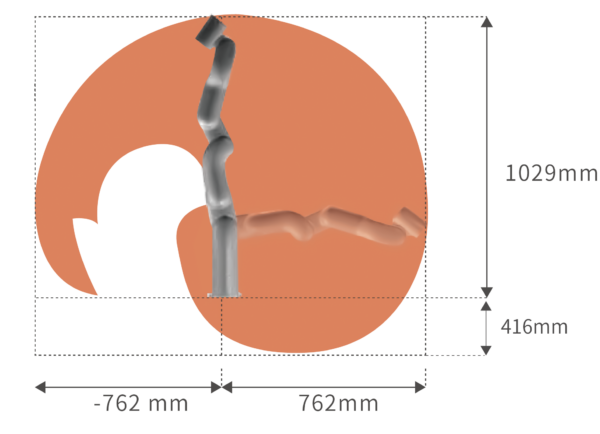

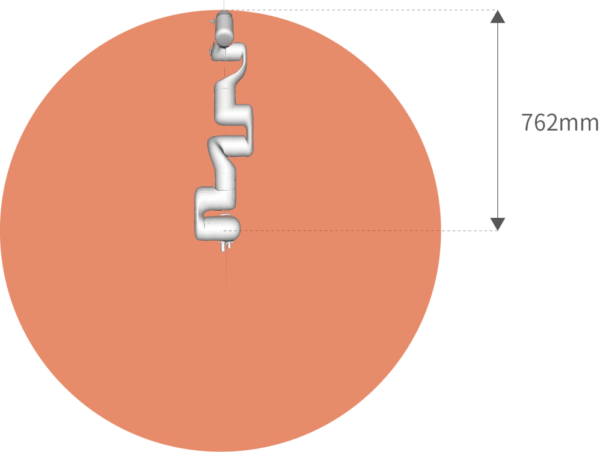

Working Range

Working space of xArm series (unit: mm)

Note: The following working range diagrams are only for safety assessment.

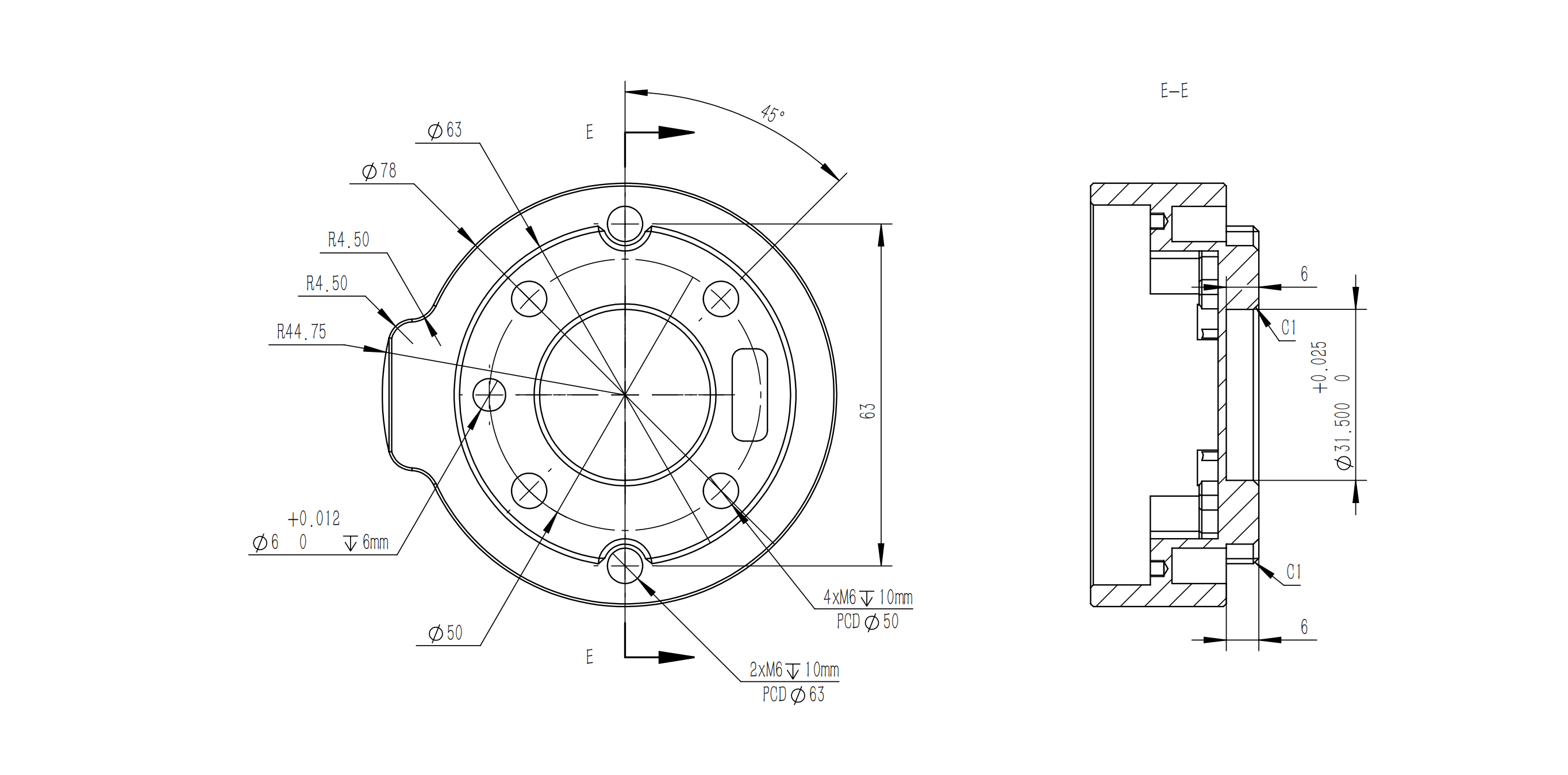

Dimension

Robot tool head

Robot base mounting (mm)

Comparison

| xArm 5 | xArm 6 | xArm 7 | |

|---|---|---|---|

| Payload | 3kg | 5kg | 3.5kg |

| Reach | 700mm | 700mm | 700mm |

| Degrees of freedom | 5 | 6 | 7 |

| Repeatability | ±0.1mm | ±0.1mm | ±0.1mm |

| Maximum Speed | 1m/s | 1m/s | 1m/s |

| Weight(robot arm only) | 11.3kg | 12.5kg | 14.3kg |

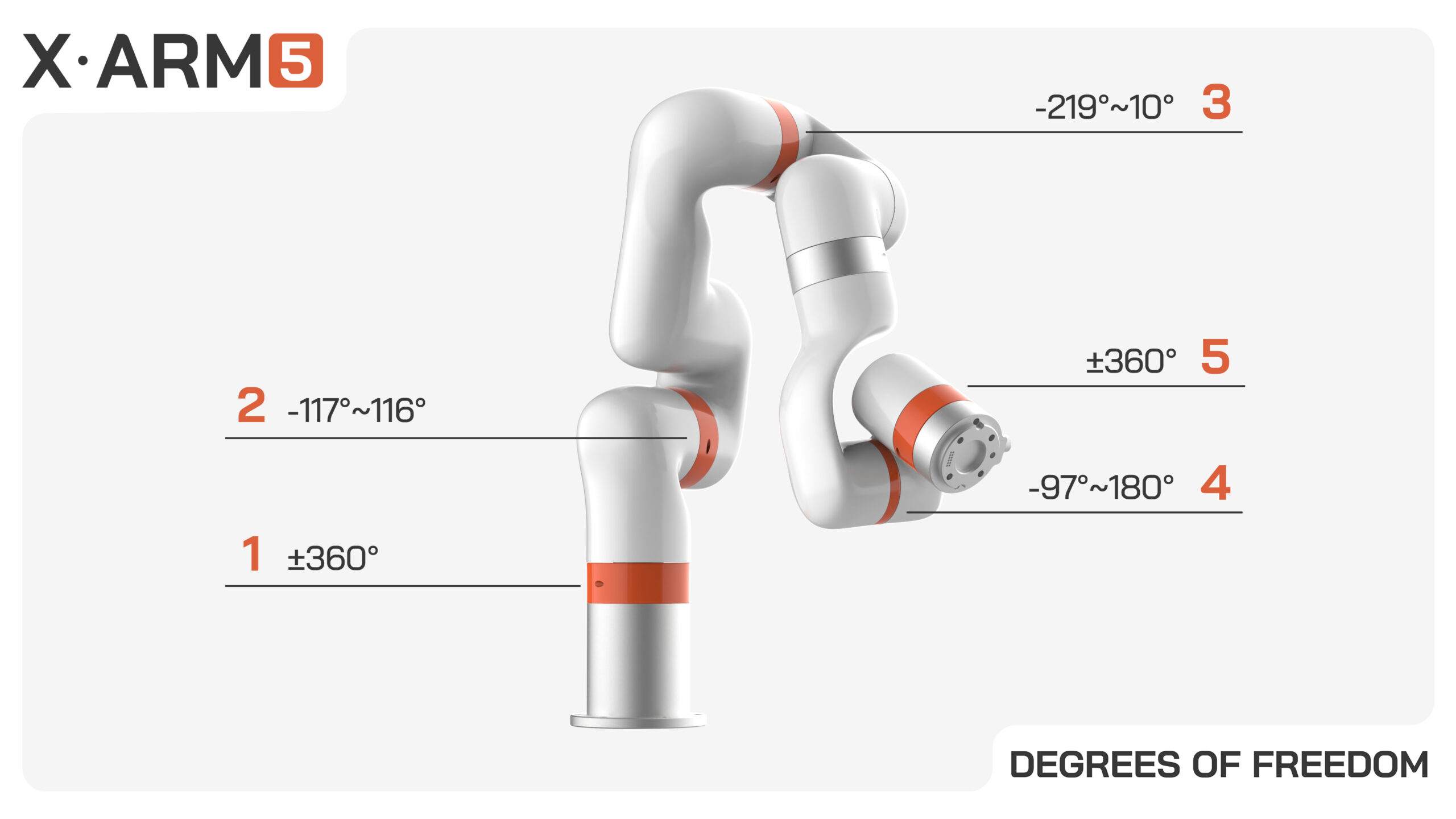

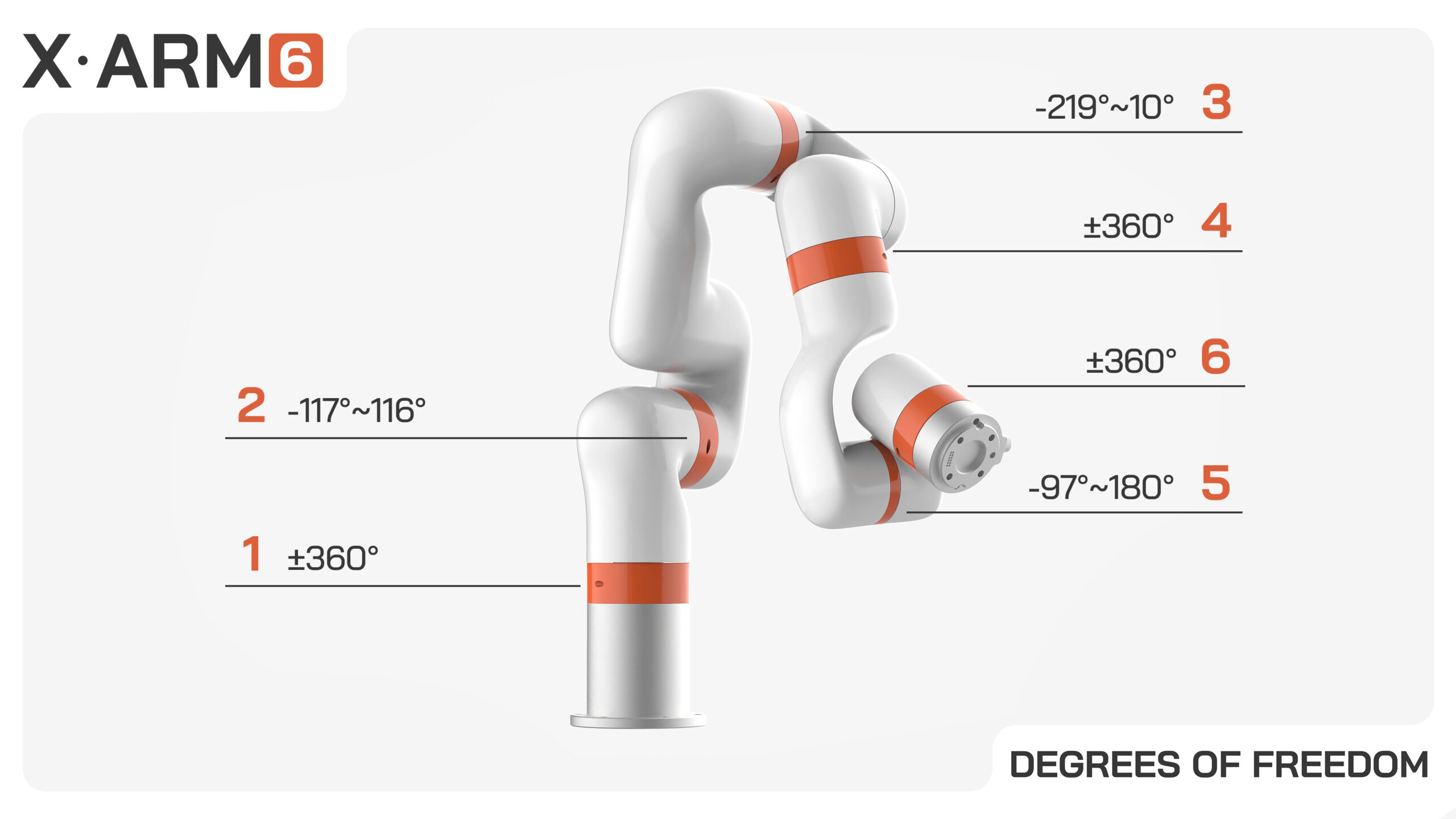

| xArm 5 | xArm 6 | xArm 7 | |

| Maximum Speed | 180°/s | 180°/s | 180°/s |

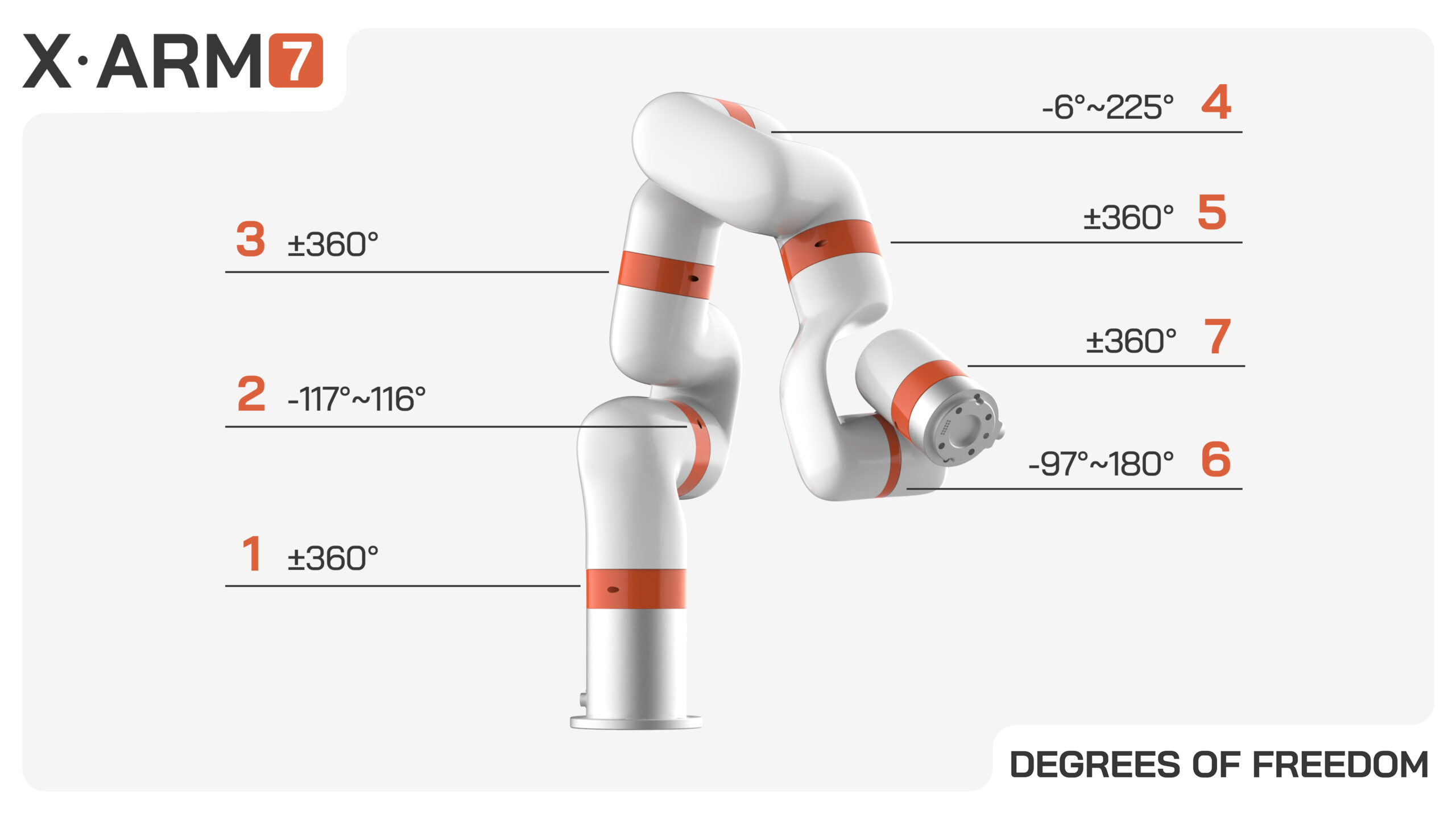

| Joint 1 | ±360° | ±360° | ±360° |

| Joint 2 | -117° ~ 116° | -117°~116° | -117°~116° |

| Joint 3 | -219°~10° | -219°~10° | ±360° |

| Joint 4 | -97°~180° | ±360° | -6°~225° |

| Joint 5 | ±360° | -97°~180° | ±360° |

| Joint 6 | ±360° | -97°~180° | |

| Joint 7 | ±360° |

Hardware

| xArm | Robot Specs |

|---|---|

| *Ambient Temperature Range | 0-50℃ |

| Power Consumption | Typical 200 W, Max 500 W |

| Input Power Supply | 24V DC,20.8A |

| Footprint | Ø 126 mm |

| Materials | Aluminum, Carbon Fiber |

| Base Connector Type | M5*5 |

| ISO Class Cleanroom | 5 |

| Robot Mounting | Any |

| End Effector Communication Protocol | Modbus RTU(rs485) |

| End Effector I/O | 2*DI/2*DO/2*AI/1*RS485 |

| Communication Mode | Ethernet |

| UFACTORY xArm AC Control Box | UFACTORY xArm DC Control Box | |||

| Input | 100-240VAC 50/60Hz | 24-72VDC | ||

| Output | 24VDC 20.8A | 24VDC 672Wmax | ||

| Weight | 3.9kg | 2.6kg | ||

| Dimension(L*W*H) | 285*135*101mm | 262*160*76mm | ||

| Control Box IO | CI*8+DI*8 (Digital Input) |

CO*8+DO*8 (Digital Output) |

2*AI (Analog Input) |

2*AO (Analog Output) |

| Communication Mode | Ethernet, RS485 Master*1 | |||

The control box is included in default.

Compatibility

Interface

Windows 10, macOS 10.10 or later, Ubuntu 12.04 or later.

API Compatibility

Interfaces with any product that has an API

Our robot API is open-source and users can make adjustments to the software as needed to interface with other products. While all integrations are possible, they all require custom code work i.e. most customers will need to write custom libraries and install software packages that are not shipped with the robot.

Open-source APIs GitHub. Learn more

Hardware Compatibility

Interfaces with any product that has

12~24V general purpose inputs/outputs

ModBus RTU (RS485)

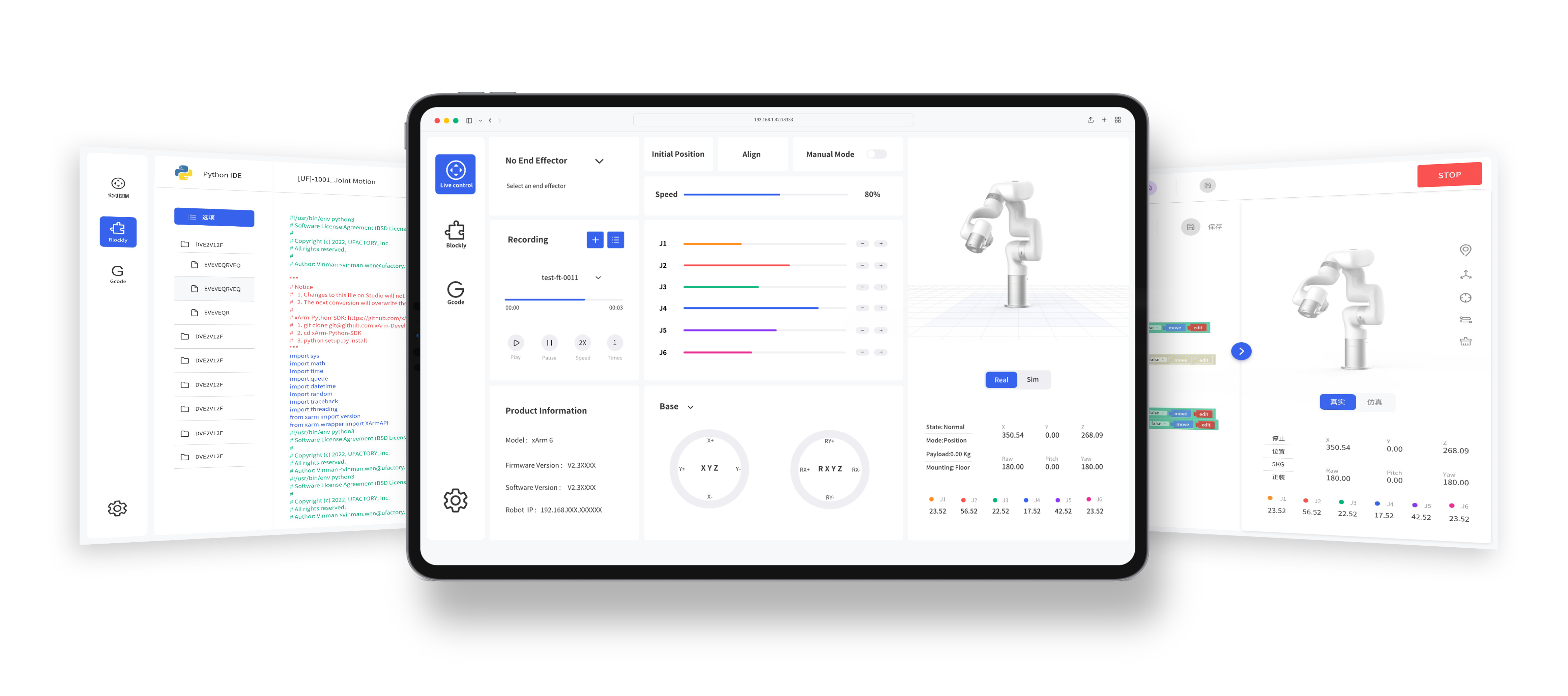

Software

UFACTORY Studio is a web-based software running inside the control box, which means no additional installation needed before running the robot. Any computer with a browser has the access after 1 minute hardware connection.

Service & Support

Warranty

1-year warranty against manufacturing defects.

Stress-tested for at least 15,000 hours of full-time operation.

Certificates

Certifications complete (CE)

Demo videos

Q&A

The lead time of xArm robot is 2-4 weeks.